What is axial clearance and how can it be prevented?Axial clearance can be used to describe the lost motion, the "dead travel", on the lead screw due to the gap between the lead screw and the lead screw nut. The term clearance is often associated with it, but the correct technical term is axial clearance..

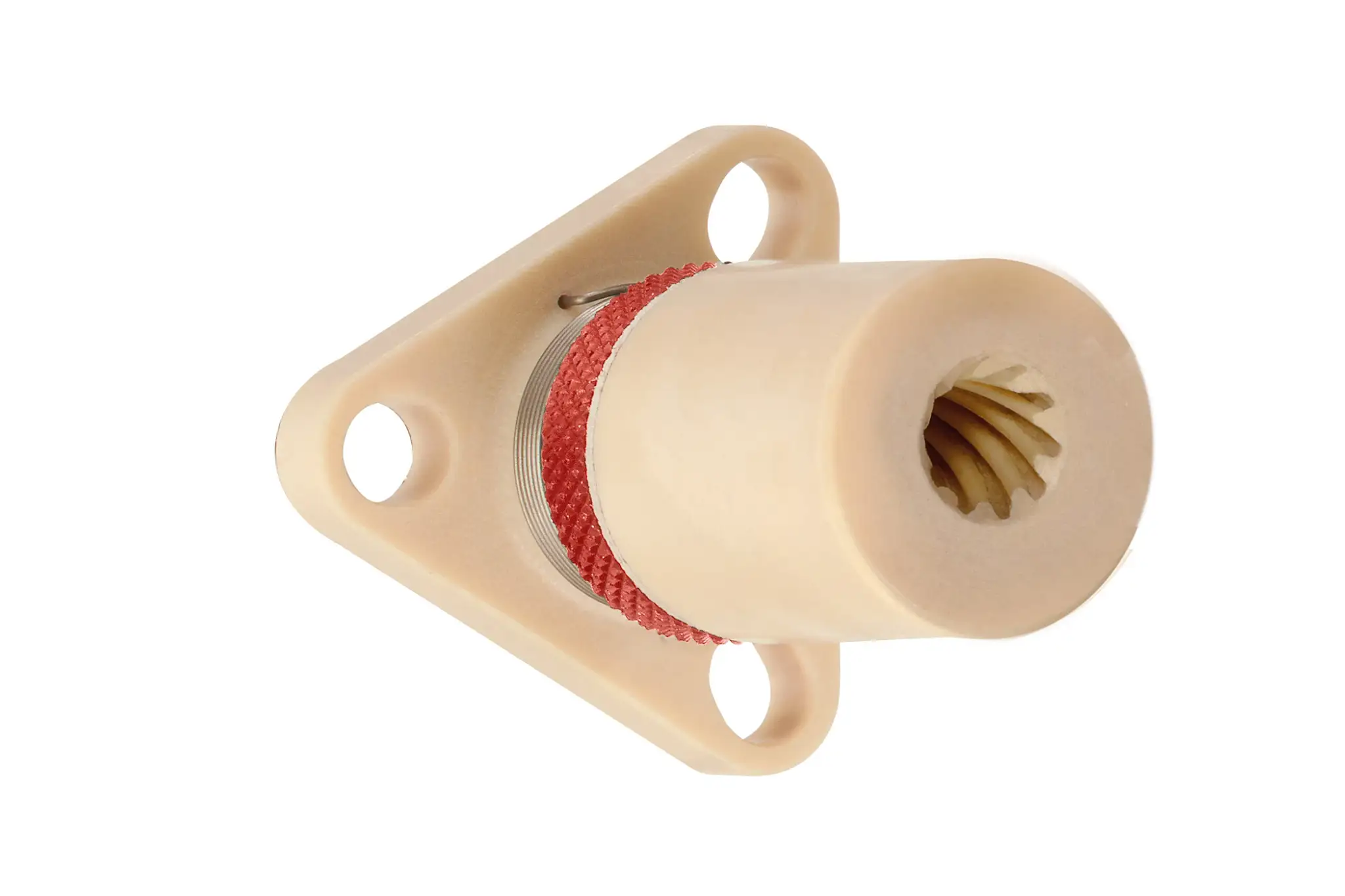

You can find more information on reducing axial clearance here. Zero-backlash lead screw nutOne of the most precise solutions is the ZB lead screw nut. It consists of several components and adjusts itself to the service life. It is particularly suitable for lead screw drives with high helix threads for quick adjustment of small loads. The clearance-free principle ensures minimal clearance over the entire service life. Ideal for precise positioning and feed movements in medical, laboratory and printing technology as well as in the broad areas of bio-sciences.

The lead screw nut consists of a support nut, an adjusting ring with torsion spring, a friction disc and the axial element. With the help of the torsion spring, the pre-tension is brought into the lead screw system.

► Life-long minimum axial backlash

► Precise positioning and infeed movements

► In dryspin® and drylin® high helix thread

► Flange lead screw nut

► Thread direction: RH

► Material: iglidur® J

Important information:for applications with high loads, high temperatures or in heavily polluted environments, a standard lead screw nut should always be used. The reason for this is that all three principles are cancelled out by too high loads. For this reason, the maximum static axial loads are specified separately for each lead screw nut model.