Change Language :

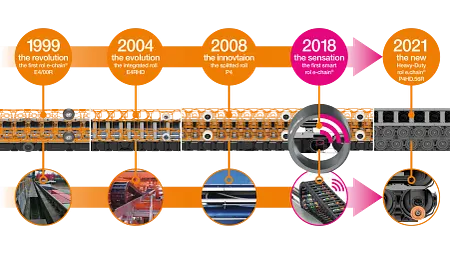

The evolution of the igus® rol e-chain®

More than 25 years of continuous improvement of the igus rol e-chains for long travels

The roller energy chain for long travels and heavy duty

The rol e-chain has been the tried-and-tested energy supply for long travels for more than years. Besides the successful design that distinguishes all of our linear energy chain systems, stainless steel rollers are added, which upgrade the energy chain to an energy supply system for heavy-duty applications. As the energy chain rolls and does not glide, it runs quietly and with low vibration. Wear is significantly lower than for designs without rollers, and the power needed for movement is also lower by as much as 57%.

The most fascinating projects with igus rol e-chains

Comparison of how rol e-chains evolved

Fail-safe even on long travels ... with igus chainflex cables

Huge range with 1,354 cable types for motor, data, bus and hybrid systems, and much more. Specially developed for moving applications in e-chains.

More information

Consulting

I look forward to answering your questions

Hennlich OOD | Хенлих ООД+359 32 621929Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr