Change Language :

Durable energy chains for gantry cranes

White paper: efficient energy supply systems for cranes in steel plants

Modern steel production is taking place in increasingly integrated steelworks. What technical challenges does this pose for the transport and conveying systems used, especially for the steelworks cranes? How can a reliable and efficient energy supply be achieved? There are two possible solutions: Festoons and energy chain. Which system offers more advantages?

Durable products for indoor cranes

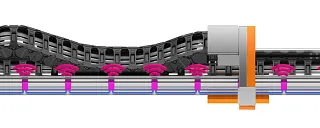

Cost-effective e-chain without guide trough

Energy and data transmission installed in 1 hour

▲ Tech up

- Energy, data, air and liquids in ONE system

- 50 % of the hall floor remains free, no guide trough required

▼ Cost down

- 88 % shorter installation time compared to a conventional standard solution with guide trough

- Less maintenance and cleaning required

Trough-integrated position measuring system EC.PP

The quick and easy-to-install position measuring system for every crane type. Provide your crane with millimetre-precise position measurement and create the option of integrating other smart plastic products, which further increases the safety and performance of the system.

Quick and easy to install

Successful application stories with indoor cranes

Tested for real-life use in the industry's largest test laboratory

This could also be of interest to you

Harbour cranes

Consulting

I look forward to answering your questions

Hennlich OOD | Хенлих ООД+359 32 621929Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr