Change Language :

Industrial 3D printing service for wear-resistant special parts in one to three days

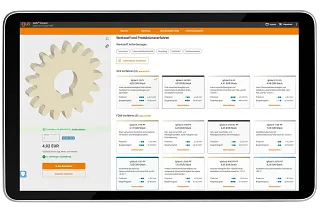

In industrial 3D printing, components are designed as digital 3D models and then additively manufactured layer by layer. The industrial 3D printing service from igus supplies parts made from their own wear-resistant plastics with no minimum order quantity. We offer solutions specifically for applications in motion where conventional materials quickly reach their limits - our plastics have up to 50 times higher wear resistance than regular 3D printing plastics. You simply upload the CAD model of your component online and receive it printed in the desired quantity.

Don't have a CAD model to hand?

With our CAD configurator, you can easily create a 3D model for different designs. We also offer you planning security with our service life calculator, which can predict the expected service life of each individual component online.

Test material quality for free!

What does the industrial 3D printing service from igus offer?

Specialised 3D printing services

Who is our 3D printing service suitable for?

Industrial 3D printing offers the ideal solution for many crucial problems. Find out more here about the typical challenges that the 3D printing service from igus overcomes. Does your application have special requirements? Then you are welcome to discuss the solution directly with an igus expert.

Has a component broken and a spare part is difficult to obtain?

A spare part can save the machine! Find out how Conti Tech Schlauch GmbH was able to cost-effectively replace a defective cross-threaded spindle using our industrial 3D printing service.

Do you need to deliver a single component or a small series quickly?

A small missing component can cost a lot of money. With 3D-printed linear drives, which were delivered in a very short time, thyssenkrupp prevented this. Find out more here!

Does the application require lightweight construction or lubrication-free components?

A metal gearbox may be too heavy for the desired movement. It also requires additional lubrication, which is not permitted in some environments. Cor.Sync solved both problems with us! Want to know how?

Special geometry of the component can only be realised at high cost?

Once you have found the perfect design for a part, it must not fall through due to the manufacturing process. Discover how the Zurich University of Applied Sciences realised its creative project with industrial 3D printing!

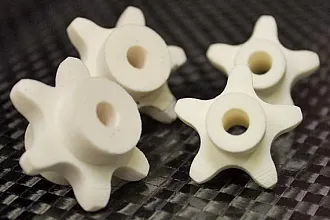

What designs can I order from the 3D printing service?

The industrial 3D printing service from igus produces customised components of all kinds. Thanks to the freedom of geometry in additive manufacturing, there are no limits to the design of a part. We print plain bearings, toothed belt discs, gears, worm wheels and grippers, among other things.

Grippers in the packaging industry

Using 3D printing instead of aluminium in the gripper production helped save up to 85% of costs and 70% of production time.

To the application example

Free gripper sample

Order a free 3D-printed sample gripper made from iglidur i8-ESD and take a thorough look at the wear-resistant laser sintering material.

Order free gripperOptions for post-processing and finishing

Mechanical rework can include, for example, the insertion of threads or thread inserts as well as the production of components with tight tolerances.

Upload CAD model and get prices immediately!

More about the CAD configurators

Order 3D printing samples free of charge

Select a sample part and test tribologically optimised 3D printing materials

See the quality and advantages of our materials for industrial 3D printing for yourself: Are you interested in 3D printed components, but would like to test them before making a final decision? Then you can order a free sample part from us.

Industrial 3D printing in practice

3D printing process in action

Discover theareas of applicationin which the igus 3D printing service has played a decisive role.

Go to the applications

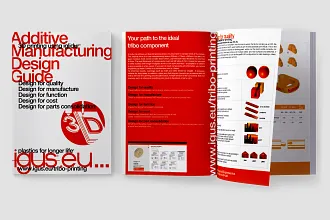

Design guide for additive manufacturing

Get practical tips on designing functional parts for manufacture in the 3D printing service here.

Download the design guideConsulting

I look forward to answering your questions

Hennlich OOD | Хенлих ООД+359 32 511326Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr