Change Language :

Whitepaper: Products for the dry cleanroom

- Understand requirements in battery manufacturing

- Correctly classify dew points and ISO Classes

Energy chains and energy chain systems directly from the manufacturers

Energy chains online shop

I am familiar with the igus energy chains and I know the required dimensions and types of movement for my energy supply system.

To the online shop

Energy chain configuration

I know the ambient variables of my application and would like to configure it conveniently online or consult an expert about an individual project.

Go to the configurators

Energy chain wiki

I am unsure what energy chain I should choose for my application and need further information.

To the information area

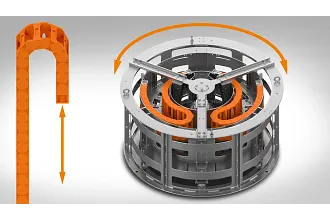

Types of movement

I know the type of movement and require the appropriate energy supply system: Horizontal movement, vertical movement, circular and spiral movement, etc.

Go to types of movementFrequently asked questions

What are energy chains?

Energy chains (also referred to as energy supply chains, e-chains or cable drag chains) are mechanical machine elements. They are used to supply and protect energy, data and signals that have to withstand the most diverse environmental influences. The decisive fact about cable guides is the symbiosis of the components moving against each other. They include cables, hoses, interior separation elements, strain relief devices and guide troughs.

The materials used have to be optimally matched to each other so that maximum operating times and a long service life are achieved. Thanks to energy chains, downtime is avoided wherever energy in the form of electricity, gas, air or fluids is supplied to moving consumers.

What energy chains are there?

Guarantee of up to 4 years on energy chains

All assembly instructions for energy chains at a glance.

Discover energy chains in interactive 3D models

Suitable cables for energy chains with 4-year guarantee

Let us inspire you - examples from the real world

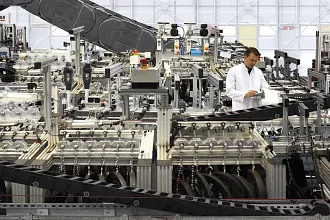

Where are energy chains used? - igus energy chains already being used reliably in hundreds of thousands of applications worldwide - from beverage vending machines to steelworks. Over 400,000 customers worldwide from 50 industries rely on igus energy chains.

Glueing instead of drilling

Compact solution for guiding cables on indoor cranes

Suspended power and data cables on indoor/jib cranes often pose a high risk as they can become tangled and tear off. With the new adhesive version of the guidelok swing GLO.S, the cable guide can be installed directly in the contour of the crane girder. A special guidelok swing rocker system allows for use with long girder lengths, ensuring low wear and cost-effectiveness.

With the new adhesive version, it is really easy to mount the cable guide securely to the crane girder - without drilling. Super-fast and simple installation with adhesive pads and assembly template.

What are the advantages of energy chains?

- Cable-friendly due to very smooth contours

- Various types of movements possible

- Lightweight, modular, strong, quiet, easy to open

- Guiding energy, data, fibre optic cable, oil and air in one system

- Configurable online

- Predictable service life

- Easy and low-maintenance, simple to install

- Can be expanded as an intelligent, self-monitoring system with smart plastics

- Large standard catalogue

3D CAD portal

Designing energy chains faster. CAD models for a wide range of systems. Designing drag chains made easy.

Our e-chain is already being used reliably in many hundreds of thousands of applications worldwide - from beverage vending machines and CNC machines to steelworks. Unsupported lengths can be bridged with ease and long travels are conceivable for a wide range of industries. It has a modular design and is therefore easy to install. Completely media-friendly and designed for the smallest bend radius, igus chains are not only suitable for tight installation spaces, but also for large, heavy and stiff cables or hoses.

Further information on energy chains

Energy chain catalogue

The energy chain catalogue can be downloaded online!

► Download here (PDF)

Tested!

Every year, 3,000 e-chain tests are carried out to withstand the toughest influences.

Recycling program

Energy chains, regardless of the manufacturer, can be recycled at igus. How does it work?

Online seminar

Benefit from the knowledge and experience of our speakers by participating in our online energy chain seminars. Interactive✓ informative✓ free of charge✓

Consulting

I look forward to answering your questions

Hennlich OOD | Хенлих ООД+359 32 621929Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr