Change Language :

Polymer plain bearings in mountain bikes with rear suspension

Dimensionally stable in wet conditions

Choice of pivot points and kinematics

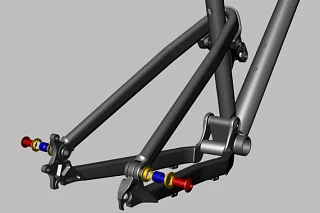

The "ConTrail MGN" is one of the top models in Bergamont's full-suspension mountain bike range. Lightweight iglidur® polymer plain bearings from igus® are used at the dropouts of the rear suspension for heavy-duty applications. The definition of the pivot points plays a very important role in the design of a rear suspension. Thomas Marquardt: "We have a precise idea of how a bicycle should ride and carry out extensive tests during development." This applies not only to the positioning of the pivot points and therefore the kinematics, but also to the choice of bearings. Bergamont originally used ball bearings at all bearing points on its "Fullys". The "Contrail MGN" is the first bike to deviate from this principle. "At the two front pivot points," says Marquardt, "i.e. at the connection between the swingarm and frame, we use deep groove ball bearings because the bearings perform a relatively large pivoting movement here. At the rear joint, on the rear axle, on the other hand, we have taken a new approach this time and are using a plain bearing."

Larger contact surface, nothing wobbles

There are good reasons for this for the designer, the most important being lateral rigidity. A plain bearing offers a much larger contact surface than a roller bearing. "Even under very heavy loads and large lateral forces, nothing wobbles," explains Marquardt.

The iglidur® plain bearings also cope very well with the high compressive load that occurs at this bearing point. "The pressure is also distributed very well over the larger surface." Bergamont was supported by igus® during the tests with the plain bearing on the rear suspension joint. This also involved selecting the optimum plain bearing material. René Achnitz, Global Product Manager iglidur® plain bearing: "In the first tests, we used the all-round material iglidur® G, but then realised that iglidur® J was more suitable."

Bearings: choosing the optimum material

It was obvious that the tests initially started with iglidur® G. This universal material for particularly economical bearings offers the widest range of applications. However, iglidur® J offers a higher dimensional stability in damp conditions, and this parameter also had to be taken into account in the bike design.

Naturally, the bikes often ride through watercourses and puddles, and they are often cleaned after use with a garden hose or even a high-pressure cleaner. Thomas Marquardt: "Even these stresses do not affect the polymer plain bearings."

Specialist dealers and bikers completely satisfied

The self-lubricating iglidur® polymer plain bearings promise a long and predictable service life. However, the sales department first had to convince the specialist dealers. Thomas Marquardt: "We had already used plain bearings a few years ago, but they were made from other materials and were too small. That's why there was a need for information and training." However, the dealers are completely satisfied with the current solution, as the feedback from bike owners has been consistently positive. The torsional strength of the bike is very good and the suspension responds very quickly, reports Marquardt.

The very careful design of the bearing point certainly contributes to this. In bike production, the bearings are pressed into the swing arm with slight pressure. In addition, a metal sleeve is inserted into the bearing, which forms the end stop for tightening the screws. This ensures that the bearings remain rotatable even after assembly work by the bike owner.

More information

Our plain bearings

Everything important about our iglidur® bearings at a glance: Standard and special part, product innovations, laboratory tests and more

iglidur® in the MTB

Rear triangle, fork, seat post and co. - application areas for iglidur® plain bearings in mountain bikes

Consulting

I look forward to answering your questions

Hennlich OOD | Хенлих ООД+359 32 511326Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr